KORLOY presents The Future Trends of Manufacturing Industry

KORLOY successfully hosted the “KORLOY Partners Fair 2025” on September 4–5 in Cheongju and September 8–9 in Daegu. Held at the Enford Hotel in Cheongju and the Inter-Burgo Hotel in Daegu, the event showcased KORLOY’s product lineup tailored to the latest trends in the manufacturing industry, as well as machining solutions for the mold, automotive, shipbuilding, aerospace, and defense sectors. The event attracted great interest from industry customers and technical professionals.

KORLOY’s Development Direction for Industry Trends

In the first session, KORLOY’s Marketing Division presented future marketing operation policies, followed by the R&D Division’s introduction of KORLOY’s response to industry trends and new products. KORLOY has focused on eight development goals: tool life, productivity, user convenience, cost reduction, machining efficiency, cutting performance across diverse materials, machining stability, and surface quality. At the seminar, KORLOY introduced its latest products designed to meet these objectives.

HQM (High Feed Square Milling)

High-feed machining is a high-efficiency process that reduces chip thickness for rapid material removal. However, it often suffers from short tool life and poor chip evacuation due to high cutting resistance. As a result, inserts can break easily, surface quality deteriorates, and tool life is significantly reduced. To solve these issues, KORLOY launched HQM. HQM features optimized helix structure inserts and a high-rigidity clamping system that reduce cutting resistance and maintain stable tool life even in high-feed machining. Additionally, its positive geometry and chip breaker improve chip evacuation which reduce damage, and enhance surface finish. With thick inserts, large screws, and heat-dissipation dimples, HQM achieves over 20% higher feed rates compared to existing solutions, boosting productivity. Furthermore, wear-resistant coatings tailored to workpiece materials strengthen edge durability and improve tool life.

Super Endmill for HRSA (Heat-Resistant Superalloys)

Heat-resistant superalloys (HRSA) such as Inconel718, Hastelloy, and Waspaloy are widely used in aircraft engines and power turbines, categorized as nickel-based, nickel-iron-based, and cobalt-based alloys. Among them, nickel-based HRSA are the most common. However, HRSA are classified as Hard-to-Cut materials due to low thermal conductivity, high strength at elevated temperatures, and work hardening. Heat concentrates at the cutting edge, making it difficult to increase cutting speeds, while edge wear and chipping drastically shorten tool life. To address these challenges, KORLOY developed the Super Endmill for HRSA 6F. With positive rake angles and irregular pitch design, it improves cutting performance and stability. Using tough carbide substrate and new coatings with excellent high-temperature oxidation resistance, it minimizes edge chipping, enhances wear resistance, and delivers outstanding tool life for HRSA machining.

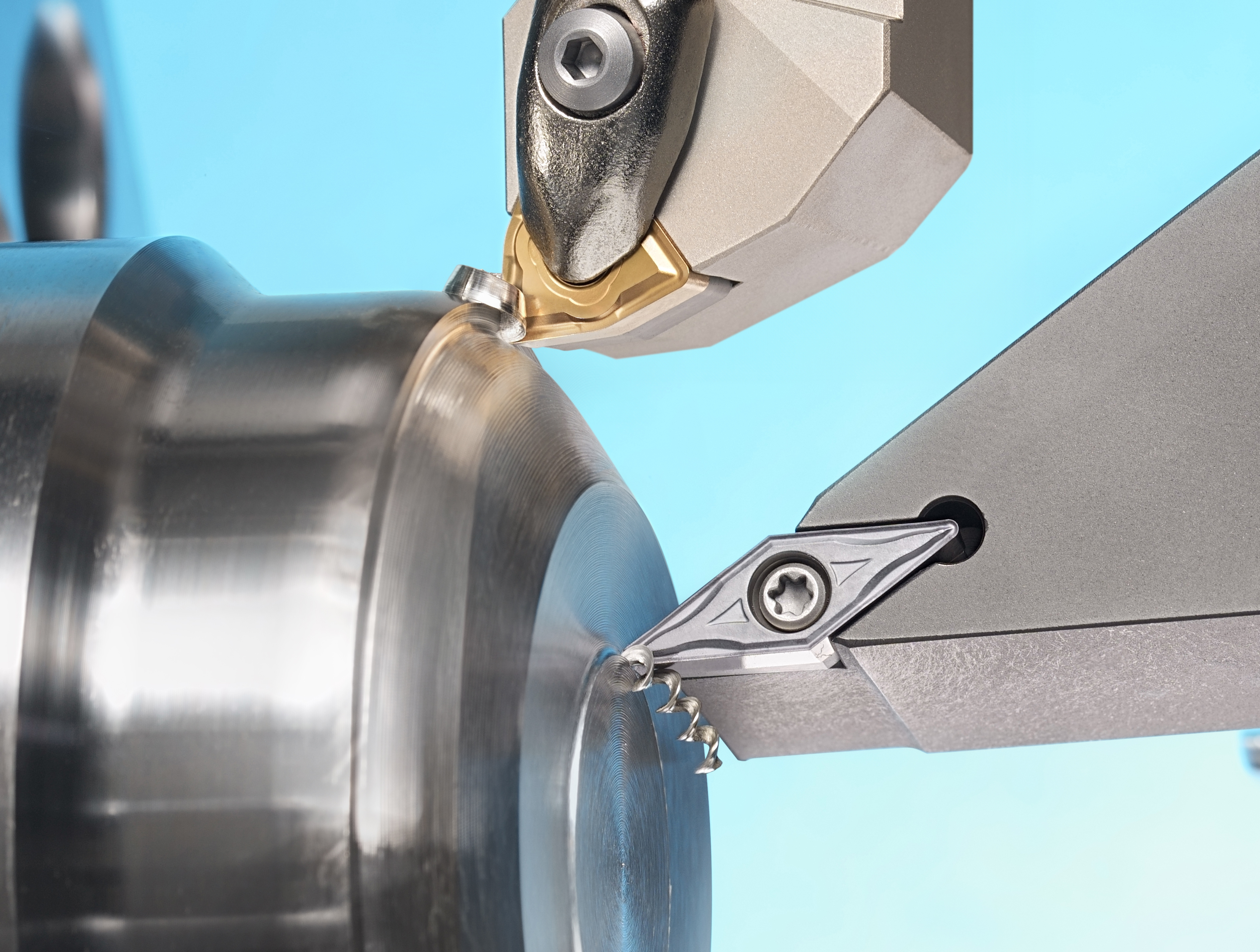

SNC805 / SPC810 (Premium Turning Grades for HRSA)

Heat-resistant superalloys such as Inconel, Waspaloy, Rene, and titanium alloys maintain mechanical and chemical properties at 700–1000℃, making them key materials in aerospace and space industries. With excellent heat resistance, tensile strength, and corrosion resistance, they are also increasingly used in the power generation and Oil & Gas industries. However, HRSA impose heavy loads on cutting tools, resulting in severe work hardening and low thermal conductivity that concentrate heat at the cutting edge, causing chipping, built-up edges, and unexpected tool breakage. To address these issues KORLOY has launched Ultra Coating grades UNC805 and UPC810, which offer improved wear resistance, chipping resistance, and adhesion resistance, and Super series turning grades SNC805 and SPC810, which further enhance these properties. The Super series delivers exceptional solutions for machining Inconel, Waspaloy, Rene, Hastelloy, Haynes, and precipitation-hardened stainless steels, offering premium performance in HRSA applications.

FP Chip Breaker (Negative Turning Inserts for Steel)

Mild steel (low-carbon steel, 0.13–0.2% C) generates long, continuous chips during machining. Without proper chip cutting, these long chips cause scratches, entanglement with the tool or workpiece, and difficulties in automated machining. To solve these problems, KORLOY developed the FP chip breaker, optimized for finishing operations and automated processes. Its dual-step design enables effective chip curling from fine finishing (ap 0.3mm) to light finishing (ap 1mm), while the first-step geometry is optimized for complex finishing of copy and taper cutting. The sharp cutting edge reduces cutting loads, minimizes vibration, and improves surface roughness. Designed specifically for finishing external turning, the FP chip breaker ensures high surface quality and dimensional accuracy across mild steel, carbon steel, alloy steel, and bearing steel, with no chip clogging.

Productivity Improvement Through Process Improvement!

Productivity improvement goes beyond enhancing tool performance. It means systematically optimizing the entire process to produce more, higher-quality products with the same resources. In addition to tool performance, factors such as power, labor, and machining costs determine productivity. KORLOY defines five key elements of process innovation and cost reduction: (1) process optimization by reducing machining time, (2) maintaining quality while reducing costs, (3) lowering labor costs, (4) reducing manufacturing costs, and (5) maximizing tool life. To support customers’ productivity improvement, KORLOY provides technical support services. These services include on-site machining diagnostics, customized solutions, and tests for process optimization. For new machining lines, KORLOY offers optimized tool selection and tooling systems, as well as internal training programs to enhance customers’ operational capabilities. In the second session, the TAS Division shared KORLOY’s vision for industry trends through case studies and databases of technical support services across various industries.

SMART FACTORY: Opening the Future

In the second part of KPF 2025, KORLOY presented smart factory solutions and customer case studies essential for the 4th Industrial Revolution Environment. Among future manufacturing trends, the Smart Factory is indispensable. To address these future manufacturing challenges, KORLOY supports customers in improving their manufacturing environments by providing smart solutions for automation projects, digital data construction control, design and tooling services optimized for smart factories, and a purchasing network. Through smart system tooling, KORLOY helps stabilize production lines, establish operational processes, and continuously support productivity improvements. This results in reduced tooling costs and enhanced mutual growth with customers.

A Venue for Shared Growth and Communication

The next day after the KPF 2025 seminar, clients and employees had a meaningful time of camaraderie through a golf tournament. CEO Jung-hyun Yim expressed his hope that "The KPF 2025 seminar would provide a platform to deliver KORLOY’s unique solutions aligned with rapidly changing industry trends, enabling mutual growth with customers in the future.”