what you’ve wanted for an innovative tooling solution.

• High speed and high feed cutting from the optimal rake angle and high helix cutting edge

RMR

High-feed machining is a highly efficient processing method that removes workpieces quickly by reducing chip thickness, and it has recently gained significant attention. However, this method also presents several challenges.

First of all, it shortens tool life due to high cutting resistance. The rapid feed rates in high-feed machining lead to increase in cutting resistance which can easily cause insert fracture. This becomes problematic when machining difficult-to-cut materials used in the aerospace and power generation industries. In addition, the chip management is challenging in high-feed machining. Volume of chips removed at once is significant, it disturbs proper chip evacuation and damages both the tool and the workpiece, resulting in reduced surface finish and tool life.

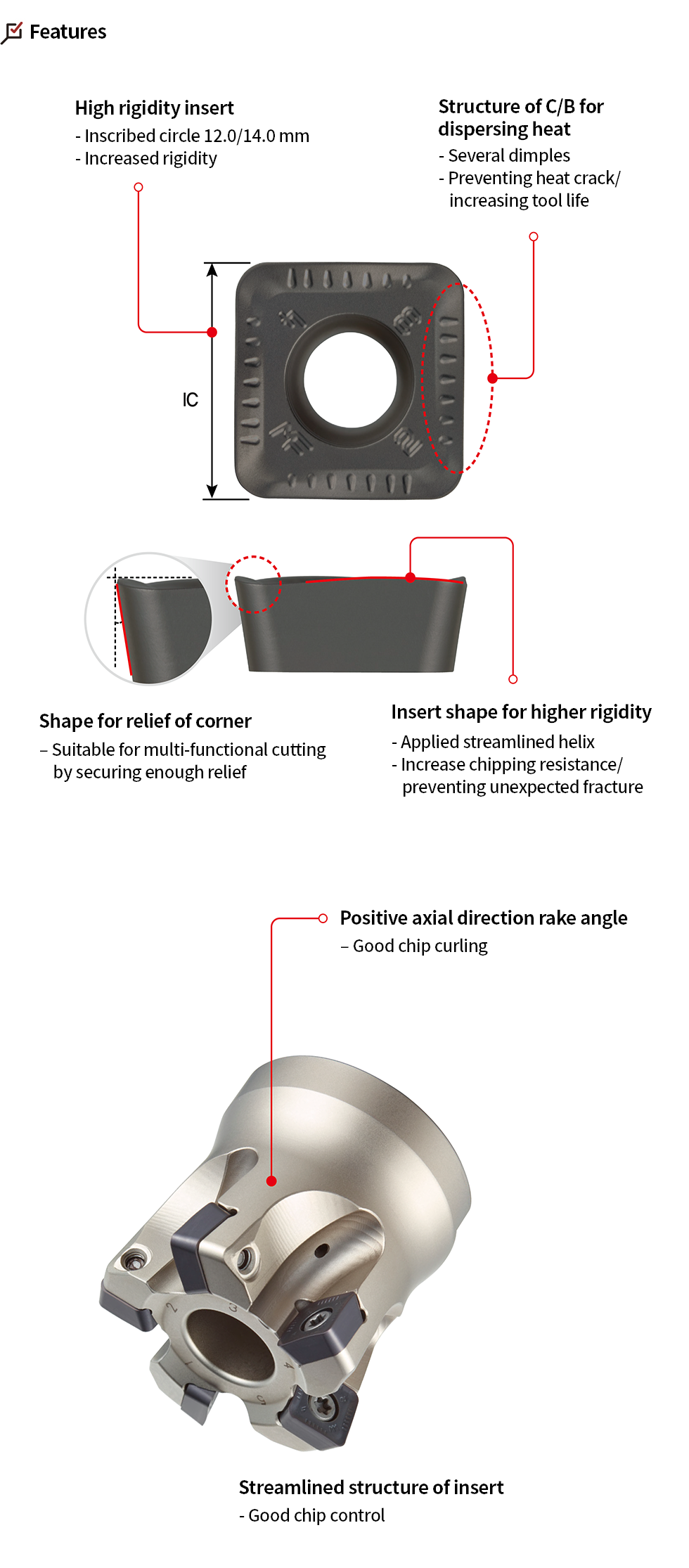

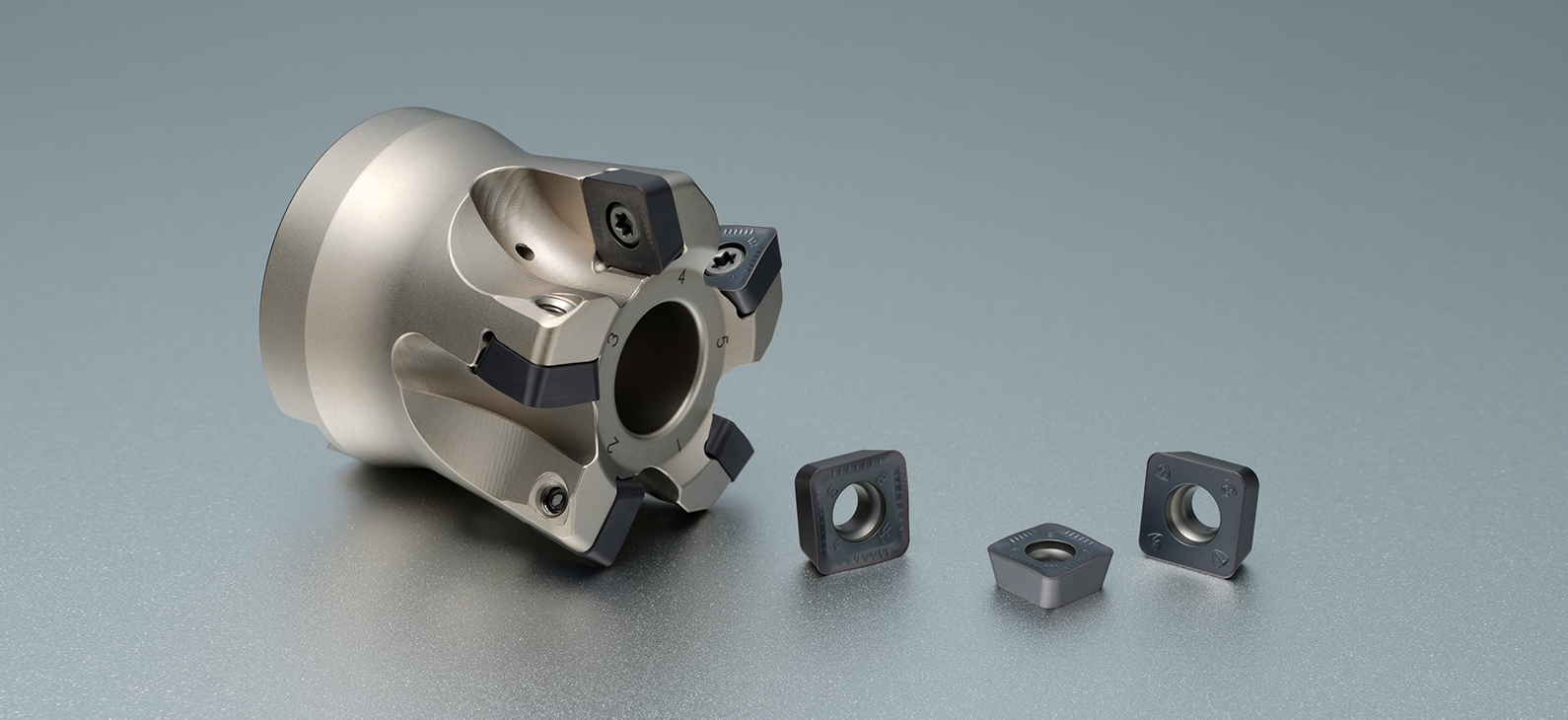

To address these issues and maximize the effectiveness of high-feed machining, KORLOY has launched the HQM.

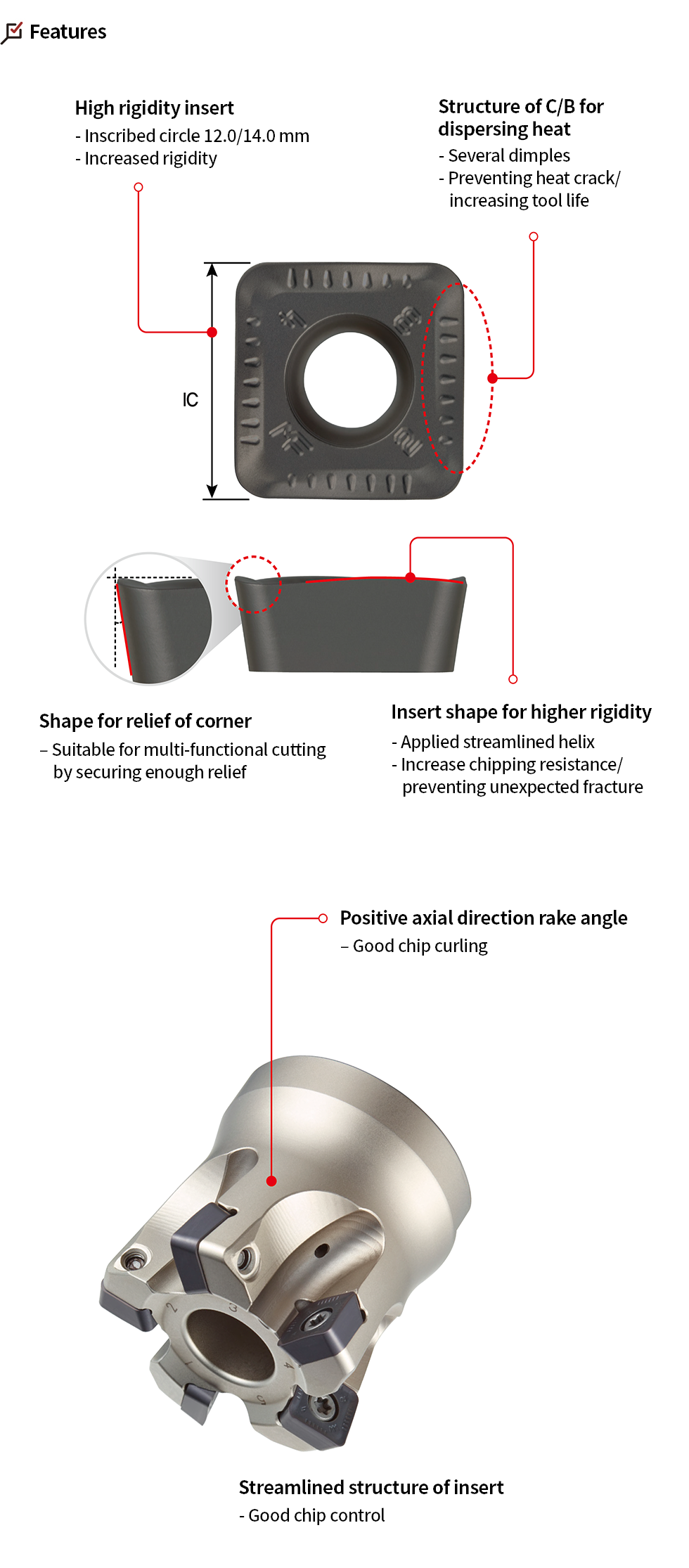

The HQM features an optimized helical structure in its insert design and a high-rigidity clamping system which reduces cutting resistance during high-feed cutting and ramping operations, preventing insert fracture and maintaining stable tool life. Furthermore, the positive geometry and

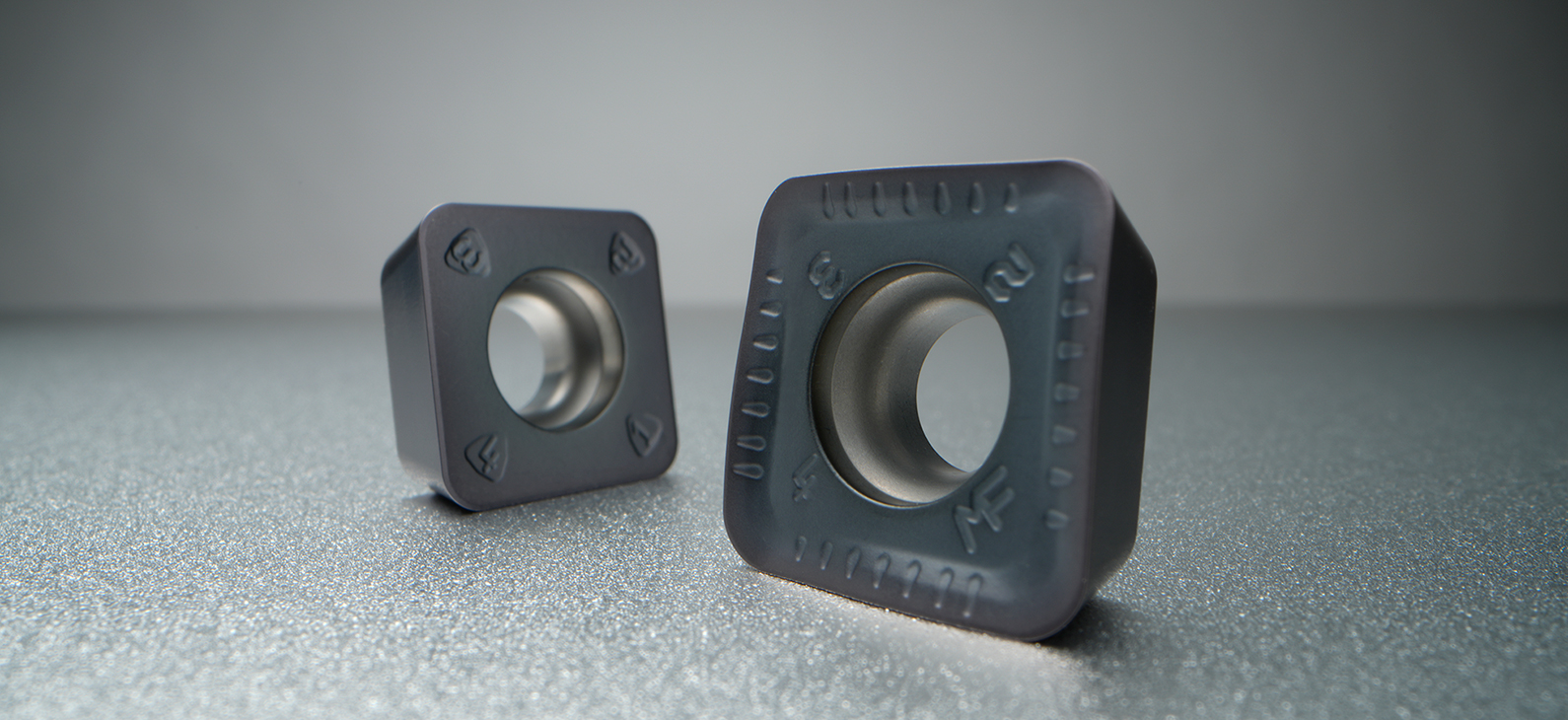

chip breaker design enable efficient chip management, protecting both the insert and the workpiece from damage, thereby extends tool life and ensures a clean surface finish. Additionally, the increased insert thickness and the application of large screws in the high-rigidity clamping system, along with a dimpled surface structure that effectively controls heat generated during machining, allow for over a 20% increase in feed rate compared to conventional high-feed machining, enhancing productivity.

The HQM provides excellent tool life by suppressing edge wear during machining and improves wear resistance through its geometric features and customized coatings tailored to the workpiece.

• Stable and high feed cutting

- high rigidity helix structure

• Good chip control

- Positive shape and sharp chip breaker

• Higher productivity

- High rigidity clamping system(increased more than 20% of existing tools’ performance)

• Effective controlling cutting heat

- The dimple shape of the insert rake surface