The diamond is a carbon crystal consisting of only pure carbon. Each carbon atom combining with 4 different atoms has a tetrahedron structure. This combining structure has higher hardness than the other substances. The diamond has relatively low thermal expansion coefficient and friction coefficient. In addition, it is stable in acid and alkaline materials and it is suitable for machining of non-ferrous materials.

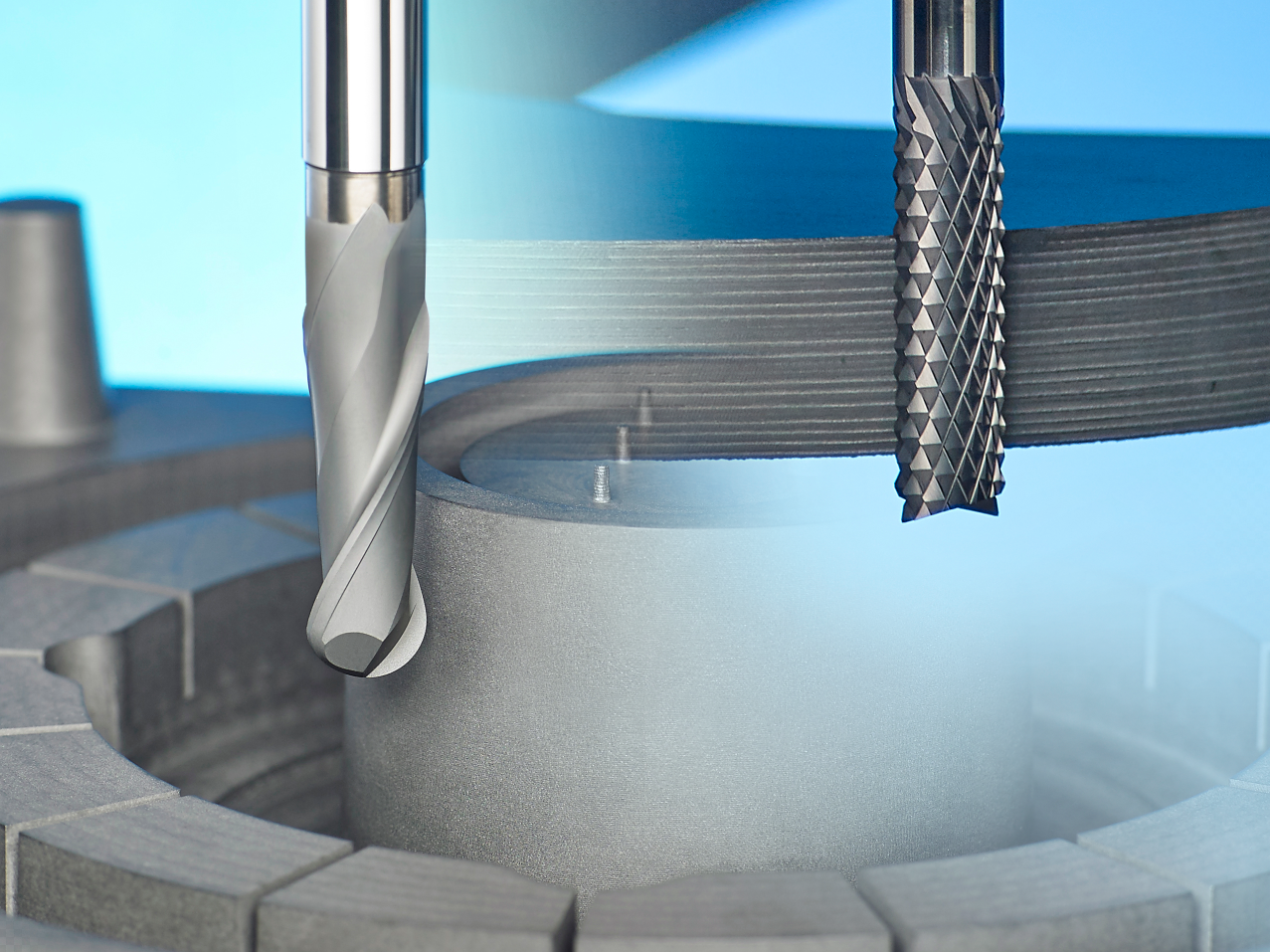

KORLOY newly launched ND3000 and ND2100 diamond coating grade for machining Non-Ferrous Metals.

ND3000 and ND2100 are diamond coating grades developed by coating system for mass production. KORLOY provides differentiated qualified diamond coated tool by controlling crystallinity, orientation and structure.

The ND3000 uses high-quality SP3 crystal structure diamond coating technology and base material to provide excellent wear resistance and adhesion between base material and coating film. Based on it, it provides a stable tool life when processing high-hard brittle materials such as graphite and ceramic.

The ND2100 uses a multi-layer coating technology that alternately laminates nanoparticles and microparticles to provide stable and equal quality for processing composite materials such as CFRP.

KORLOY aims to realize customer satisfaction through the ND3000 and ND2100.