KORLOY Unveils the Future of Aerospace and Defense Component Machining

KORLOY, a company specializing in cutting tools and machining solutions for the aerospace and defense industries, successfully hosted the "KORLOY Partners Fair 2025." This event which was held on May 14th, at the Ambassador Hotel in Changwon, covered a wide range of topics including technologies for hard-to-cut materials, product lineups optimized for complex shape machining, and process optimization strategy for each aviation material. The seminar drew strong interest from industry clients and technical professionals.

KORLOY's Targeted Strategies for the Aerospace and Defense Industries

Part 1 of the seminar was focused on the characteristics of key materials used in aerospace and defense industries, along with the main challenges involved in machining them. In part 2, case studies of aerospac and defense components machining improvements, case studies of collaborative tooling projects with clients, and KORLOY’s flagship tools developed specifically for high-precision and hard-to-cut aerospace components were shared.

Aluminum alloys are primarily used in aircraft structural components such as wing ribs and tail faces. However, they have been reported that chips stuck to tools during processing and precision deterioration occurs frequently due to heat. Composite materials, while lightweight and highly durable, are widely used in aircraft body frames, but machining them poses challenges in maintaining quality due to wear and burr formation.

Heat-resistant alloys, known for their high-temperature strength and corrosion resistance, are mainly used in key aircraft engine components like turbine cases, disks, shafts, and blisks. However, due to their low thermal conductivity, tool temperature rises sharply during cutting, which significantly increases the risk of tool breakage. Titanium alloys are suitable for high-intensity parts such as engine and landing gear components, but since they are extremely difficult to machine and leads to short tool life, they are classified as high-machining difficulty materials.

Ahn Sun-yong, Deputy Director of Research of KORLOY, stated, “For such hard-to-cut and high-precision materials, KORLOY analyzes the physical properties and processing conditions of each material, and offers optimized cutting strategies and product solutions, helping customers in the aerospace and defense industries overcome their technical challenges.”

Product Solution Lineup for Hard-to-Cut Materials

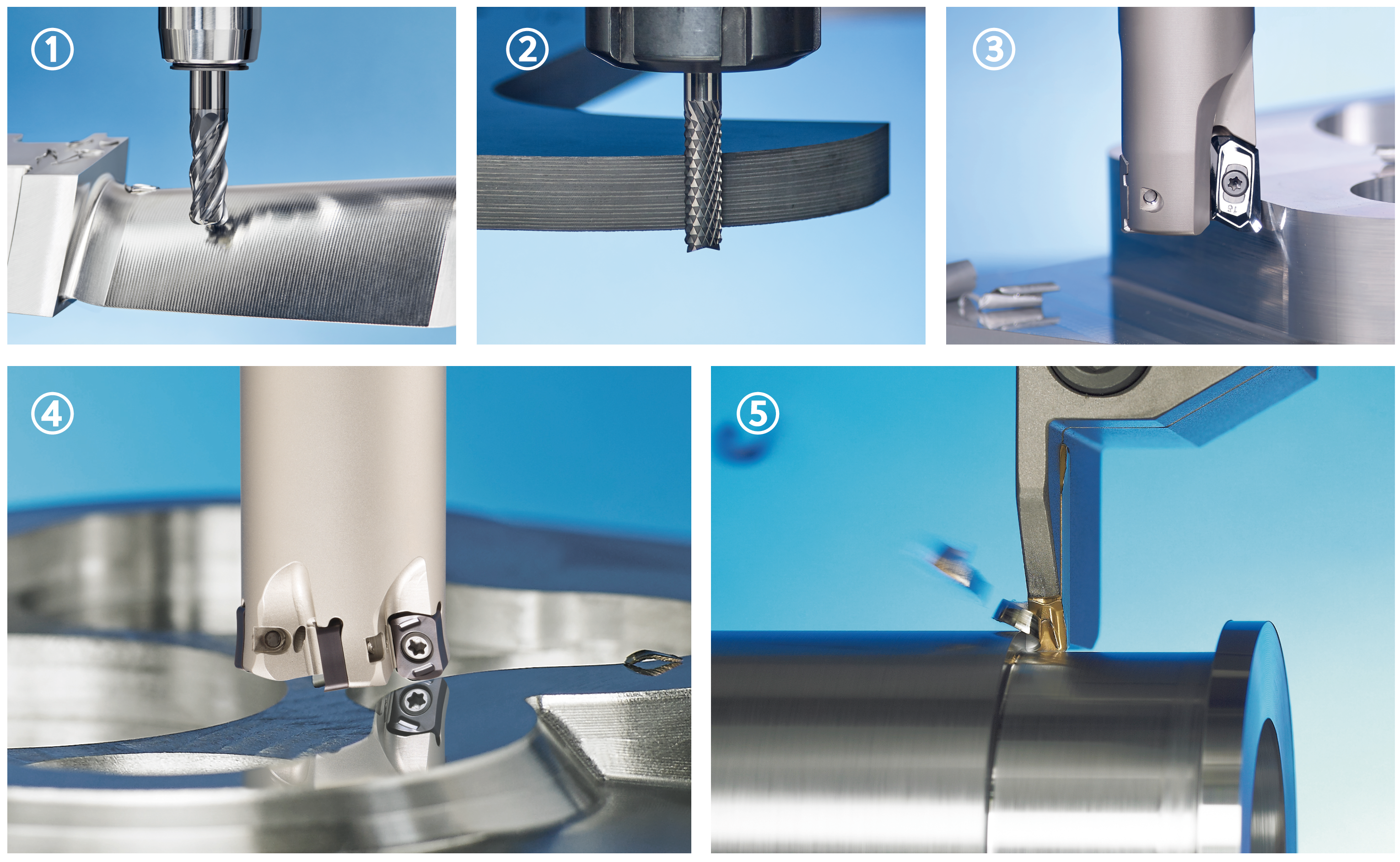

Based on the material characteristics discussed in Part 1, KORLOY introduced five key products designed for machining hard-to-cut materials and high-precision components.

First, the "Super Endmill" (Photo 1) is optimized for machining heat-resistant alloys like Inconel and titanium. Its streamlined flute design and high-lubricity thin-film coating reduce cutting heat and facilitate smooth chip

evacuation. This design enhances tool life and ensures stable machining quality even in high-temperature conditions.

The "Dia Coating Endmill" (Photo 2), designed for CFRP (carbon fiber reinforced plastic) machining, uses a high-hardness diamond coating to lower friction and improve wear resistance. Reduced burr formation and excellent surface finish has been realized by improved cutting edge.

The "Pro-V Mill" (Photo 3), developed for high-speed and aluminum machining, features a reinforced clamping structure to maintain insert stability at high rotation speeds. Its optimized tool design enables superior surface finish and perpendicularity, offering improvements in both productivity and machining quality.

The "HFMD" (Photo 4) is a high-feed milling tool equipped with a square-shaped 4-corner insert. It reduces cutting resistance through high rake angle and helical edge design, and allows multi-clamping. Especially under high-speed, high-feed conditions, it suppresses vibration and prevents tool damage or breakage, enhancing both productivity and tool life.

Finally, the "KGT" (Photo 5) is a multifunctional tool specialized for grooving and parting operations. Its clamping-based structure minimizes vibration, while various chipbreaker options and high precision-insert design provide excellent dimensional accuracy and machining quality.

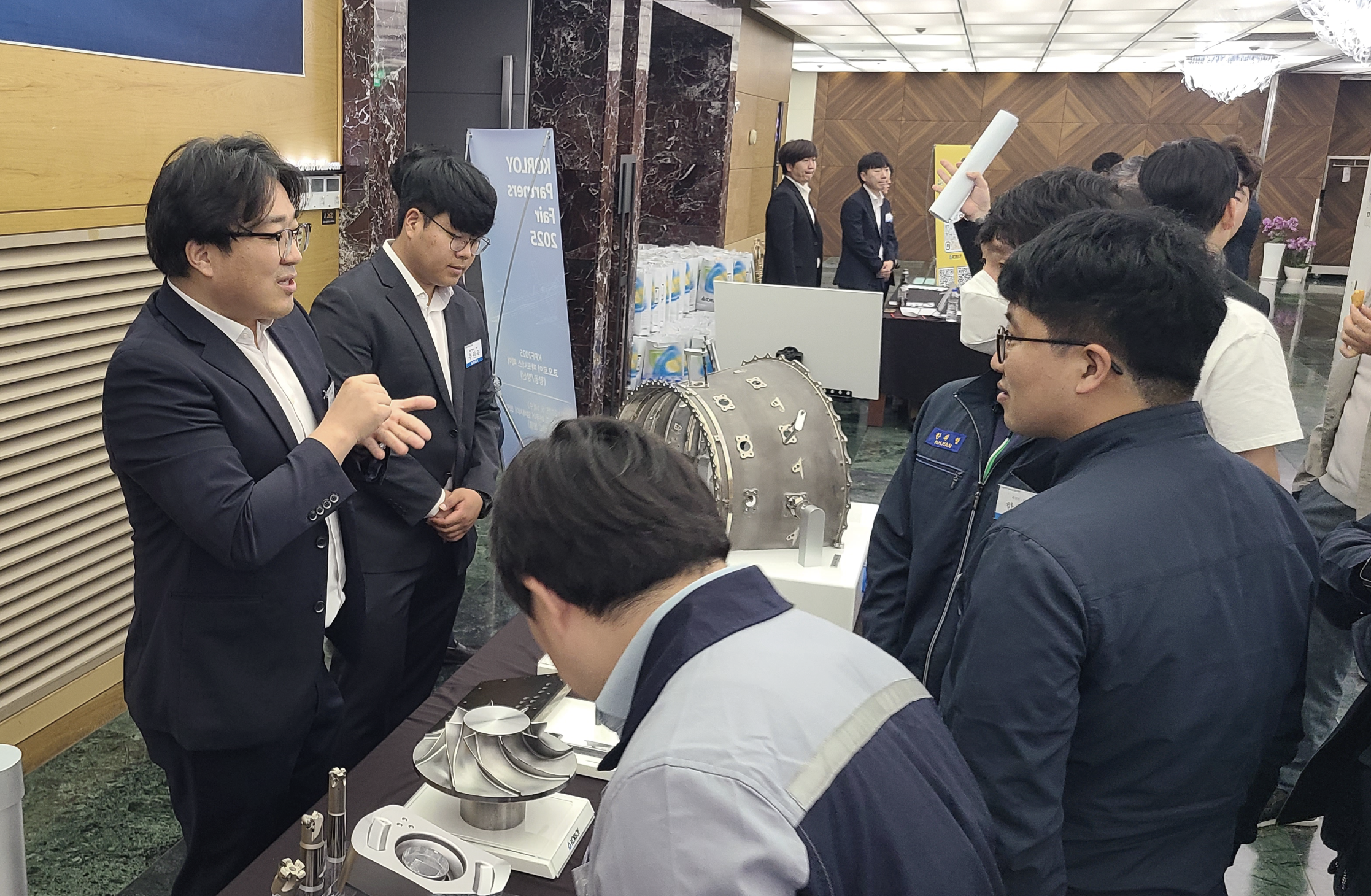

Field-oriented product displays and technical consultation

At the seminar, Koroly's latest tools for machining aerospace and defense parts were on display, and real-time technical consultations were actively held between customer engineers and KORLOY's AIT (AeroSpace & IT) team. Customers directly inspected the displayed products and inquired about the application areas and technical features of each product, and KORLOY shared customized processing strategies along with practical explanations.

A Venue for Industry Networking and Customer Engagement

This seminar went beyond a simple technical presentation, fulfilling its role as a platform for interaction by expanding contact points with customers and sharing the flow of technology within the industry. In the latter part of the event, a prize giveaway and dinner followed, during which networking among participants occurred naturally.

KORLOY’s Direction for Responding to Future Industries

At the event, KORLOY President Jung-hyun Yim stated that the company will designate the aerospace and defense industries as key strategic sectors for the future and will continuously strengthen its technologies and product development for hard-to-cut materials. Especially, he added, “To respond to the rapidly changing material trends and increasing demands for precision machining in the aerospace industry, we will expand technology-based cooperation with customers and continue to provide customized machining solutions.”

KORLOY Partners Fair 2025 served as a clear signal that the company is moving beyond the role of a simple tool manufacturer and is strengthening its position as a technology partner across the entire aerospace and defense manufacturing environment. The seminar presented integrated solutions that went beyond tool quality and performance, connecting materials, machining strategies, and process optimization, and served as an important milestone for assessing KORLOY’s future market strategy.