what you’ve wanted for an innovative tooling solution.

• Roughing grade series for high hardened steel

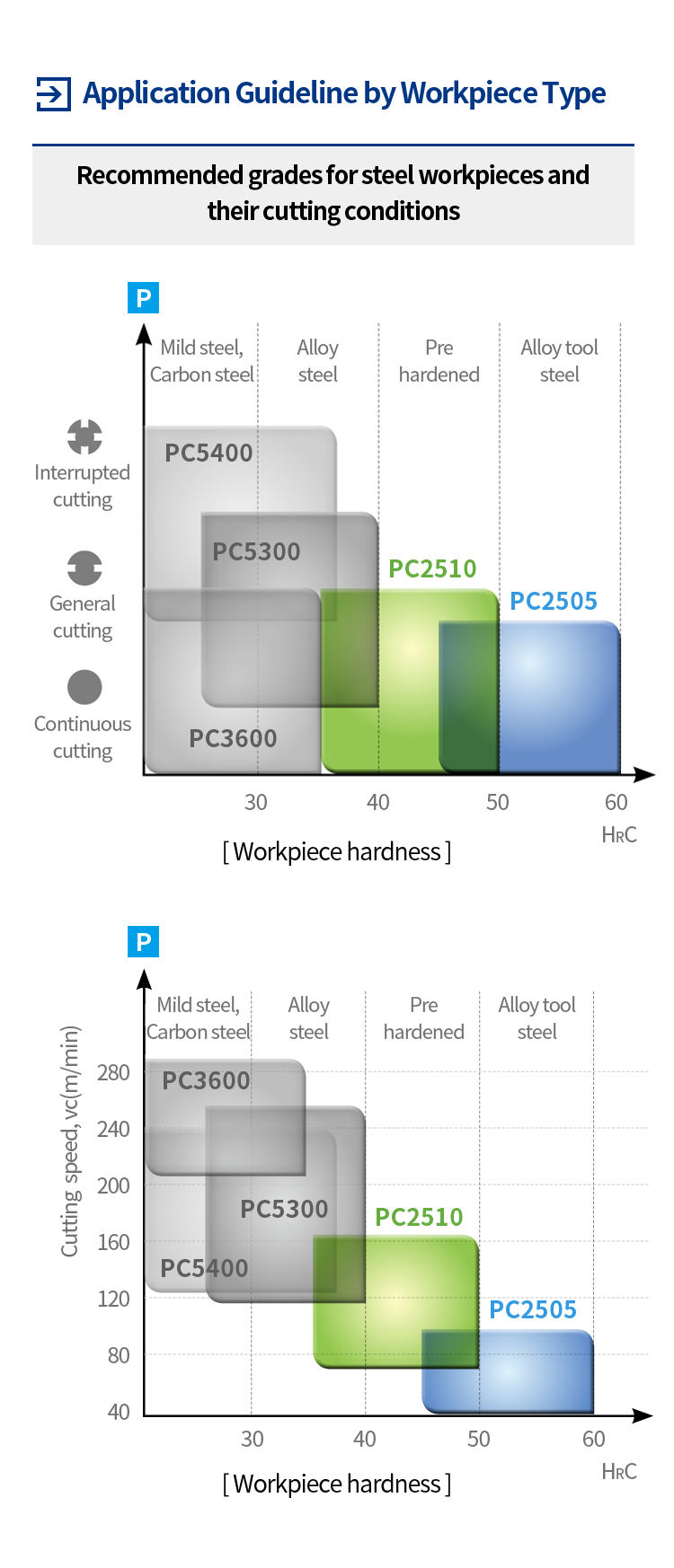

- PC2505 (for high hardened steel ≥ HRC45)

- PC2510 (for high hardened / pre-hardened steel ≤ HRC35~50)

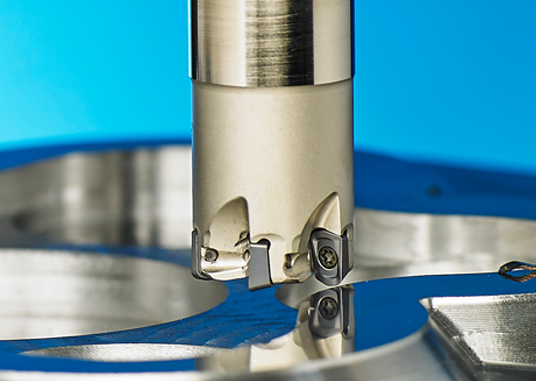

• High feed and high efficiency machining

- Combination with high feed tools will deliver higher productivity and stable tool life in high feed and high hardness machining

PC2505 · PC2510

Machining workpieces with high hardness over HRC40 generally involves rapid tool wear due to friction between tools and workpieces. Machining speed should be lower due to high impacts caused by high hardness of workpiece. But lower speed cutting may cause built-up edge and chipping which affect shortened tool life.

KORLOY provides an advanced milling solution for machining those high hardened steels.

The PC2505 is a grade for workpieces with ultra high hardness. Its excellent wear resistance helps extend tool life when machining pressed die steel and heat treated steels of high hardness over HRC45.

PC2510 is a grade for machining high hardened steel and pre-hardened steel. Its high toughness ultrafine substrate is ideal for interrupted cutting of high hardened steel and wet cutting with massive thermal shock.

ㆍCombination of the ultra high hardness substrate and coated layers

- Provides excellent wear resistance

ㆍSmooth surface treatment

- Reduces built-up edge in low speed machining of high hardened steels

ㆍExclusive grades ideal for high hardened steels